(not included in SCU, CDA or CE)

Issues » Climate and energy » Map of key low-CO2 emissions projects in the EU steel industry

Low-CO2 emissions projects in the EU steel industry

Maps of key low-carbon steel projects

Downloads and links

Recent content

The European steel industry is on an ambitious path to cut carbon emissions by 55% by 2030 compared to 1990 levels (equivalent to over -30% compared to 2018 levels), and to achieve climate neutrality by 2050.

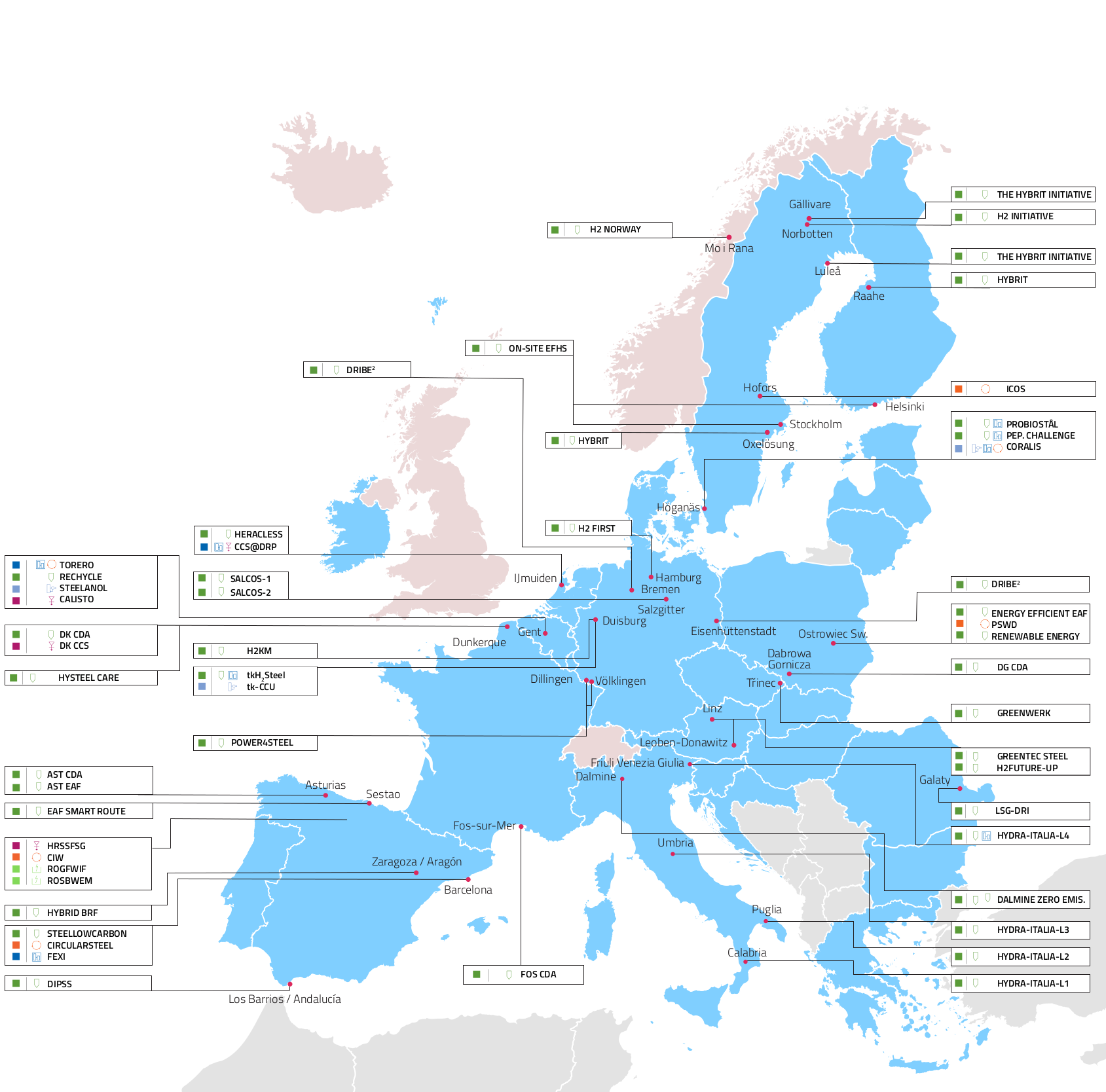

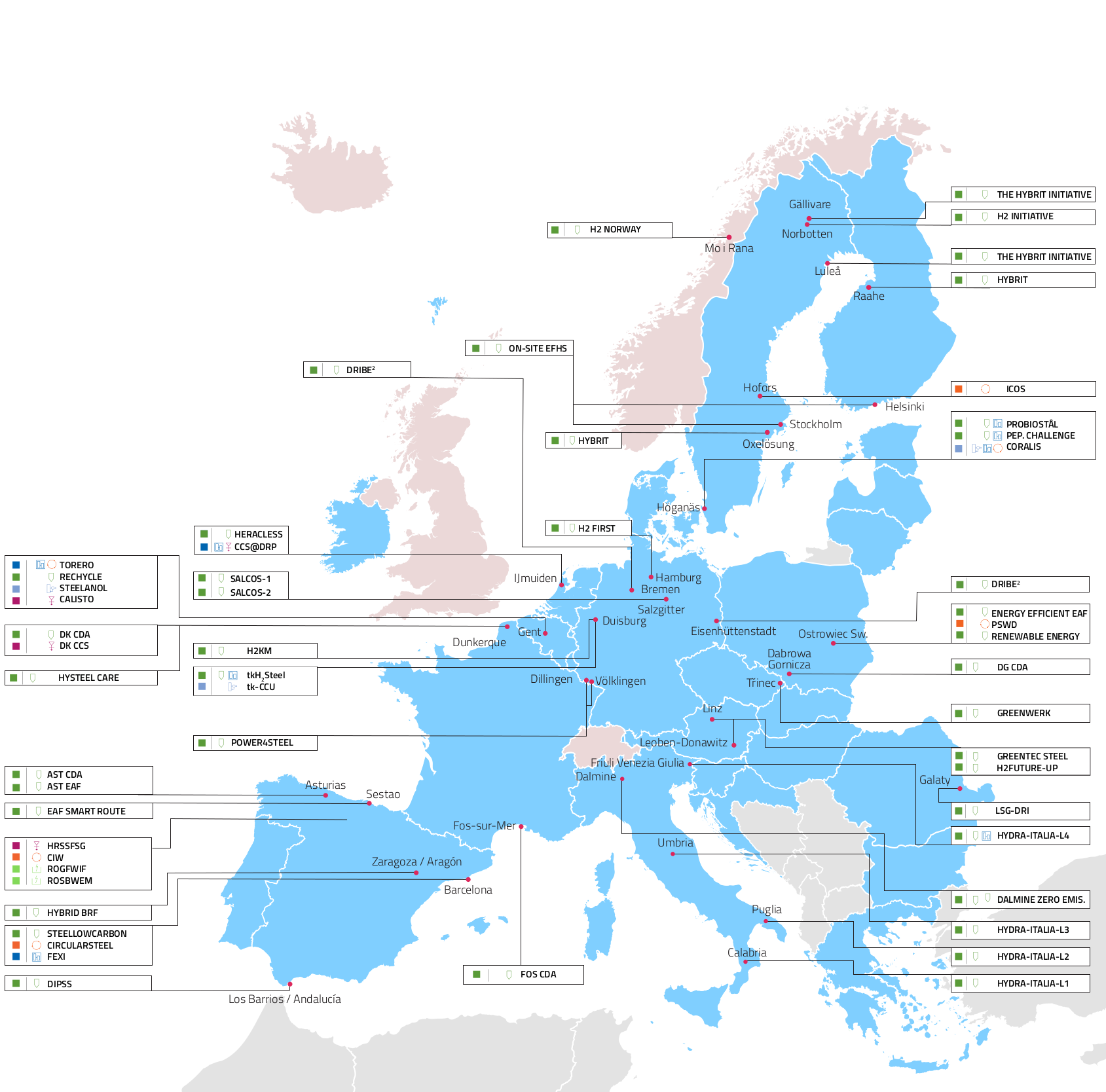

The above map shows examples of key low-CO2 projects that can help to achieve a substantial reduction of CO2 emissions in the EU steel industry. These projects (currently 60, but numbers grow by the month) will almost all start before 2030 and have the potential of reducing CO2 emissions by 81.5 million tons per year by 2030. This is equivalent to a cut of more than 1/3 of direct and indirect CO2 emissions of the European steel industry in just eight years from now, in line with the EU climate targets.

All these projects have a Technology Readiness Level (TRL) of at least 7 out of 9.

The financial needs until 2030 are estimated today at €31 billion for capital expenditures (CAPEX) and €54 billion for operating expenditures (OPEX), totalling €85 billion.

The successful transition of the EU steel industry towards CO2 neutrality by 2050 depends on the availability of cost competitive low-CO2 energy carriers (especially electricity and hydrogen) and related infrastructure (including for CO2 transport and storage).

The above projects will require annually about 75 TWh electricity for the operation of steel processes and about 2.12 million tonnes of hydrogen (corresponding to about 90 TWh of electricity, if this hydrogen is produced via water electrolysis), which means in total about 165 TWh of decarbonised electricity by 2030. This is the equivalent of the double of Belgium's yearly consumption.

This corresponds also to an increase of 100% of today’s electricity consumption of the EU steel industry. Currently, the EU steel industry consumes annually about 75 TWh of electricity, which are partly purchased from the external grid and partly self-generated through gas power plants using process gases of the steel industry as well as through top-gas recovery turbines.

The steel sector is at highest risk of carbon leakage and the most impacted by unilateral climate policy among energy intensive industries[1]. In this context, ensuring a level playing field with third country competitors is essential for the transition to climate neutrality of this sector; the success of the above low-CO2 steel projects and their envisaged emissions reduction require a supportive legislative framework that effectively addresses carbon leakage both during and after their implementation.

EUROFER will regularly update the projects map, taking into account ongoing developments.

[1] European Commission, In-Depth Analysis in Support of the Commission Communication COM(2018) 773 “A Clean Planet for all - A European long-term strategic vision for a prosperous, modern, competitive and climate neutral economy” page 221

Brussels, 22 October - Ahead of the European Council meeting on 23 October, Europe’s steel and automotive industries — two strategic pillars of the EU economy — are issuing a joint call for a realistic and pragmatic pathway to transformation and keeping investments in Europe. Together, these sectors form the backbone of Europe’s industrial strength, supporting over 13 million jobs in automotive and 2.5 million in steel (directly and indirectly), and driving innovation across entire value chains.

Brussels, 10 September 2025 – Reacting to today’s State of the Union Address delivered by Commission President Ursula von der Leyen, Axel Eggert, Director General of the European Steel Association (EUROFER) said:

Brussels, 11 July 2025 – The delay and ongoing uncertainty about a deal on tariffs between the EU and the U.S. further worsens the crisis for the European steel industry. U.S. steel tariffs at 50% are adding fuel to an already explosive situation, putting the sector at risk of losing all its exports to the U.S. and facing a surge of deflected trade flows redirected from the U.S. to the EU market. The lack of bold and timely implementation of the Steel and Metals Action Plan is further accelerating the sector’s deterioration, says the European Steel Association.